We expand our repertoire of technological solutions (Part 2)

We carried out this process of introspection and evolution, which coincides with our 17th anniversary, alongside the development of technological projects for our clients. One of them was for Werfen.

A worldwide leader in in-vitro diagnostics, the company took the strategic decision to migrate from IBM SmartCloud to Microsoft’s Office 365 cloud. The project required Werfen’s SmartCloud services to coexist for a specific period alongside the new Office 365 cloud. To achieve this, a coexistence strategy was executed using Binary Tree’s CMT software.

In addition to this migration process, we must add the process we managed for General Optica, a company dedicated to the manufacture, design and distribution of optical fashion, who decided to move all their corporate mailboxes to Microsoft Office 365.

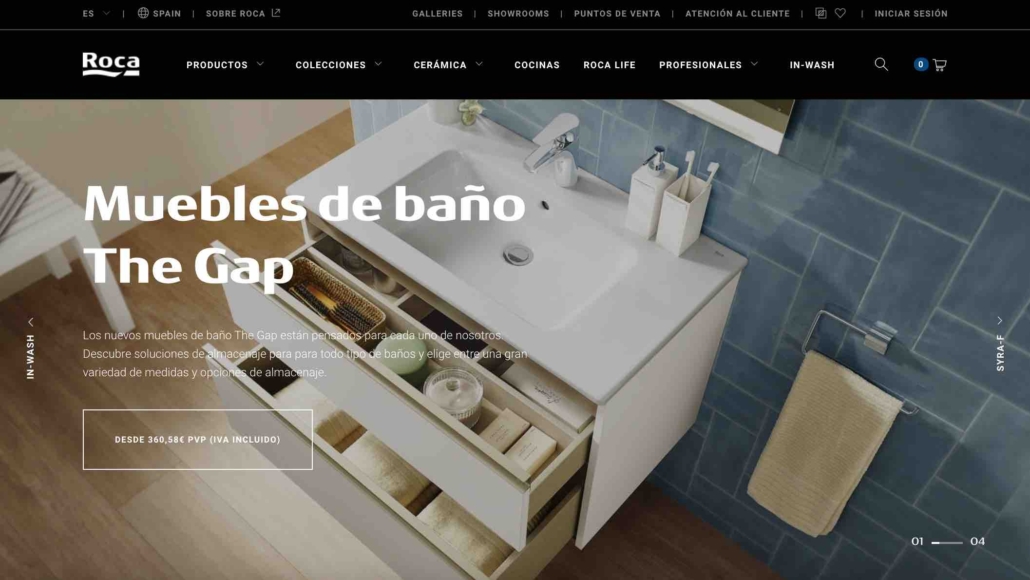

Roca takes the leap to Akeneo PIM 4.0

In 2020, Akeneo launched a new version of its PIM–Product Information Management system, Akeneo PIM 4.0. Precisely one of the most outstanding projects we carried out last year was linked to this launch and consisted of a migration from Akeneo 2.3 to Akeneo 4.0, which we carried out for Roca. .

To do that we had to clear the considerable technological leap between the two versions, especially with regard to the graphical interface, which in the current version was developed using React. We also developed the connector with Cloudinary DAM and created relationship attributes between products and entities.

We managed migration from Akeneo 2.3 to Akeneo 4.0 for Roca

Optimization of Brico Depôt’s eCommerce infrastructures

Another project linked to the eCommerce sector was one carried out for Brico Depôt, a French chain of DIY, garden and home renovation products. It consisted of optimizing its online stores in Spain and Portugal, developed with Magento using the Azure infrastructure, Microsoft’s public pay-per-use cloud.

Restrictions on physical stores imposed because of the Covid-19 pandemic sharply increased traffic to the Brico Depôt online store. In order to maintain optimum performance and to improve scalability, it was necessary to redefine its architecture in record time. To do that, we created elastic infrastructures in Kubernetes, a market-leading platform ideal for hosting cloud-native applications that require rapid expansion.

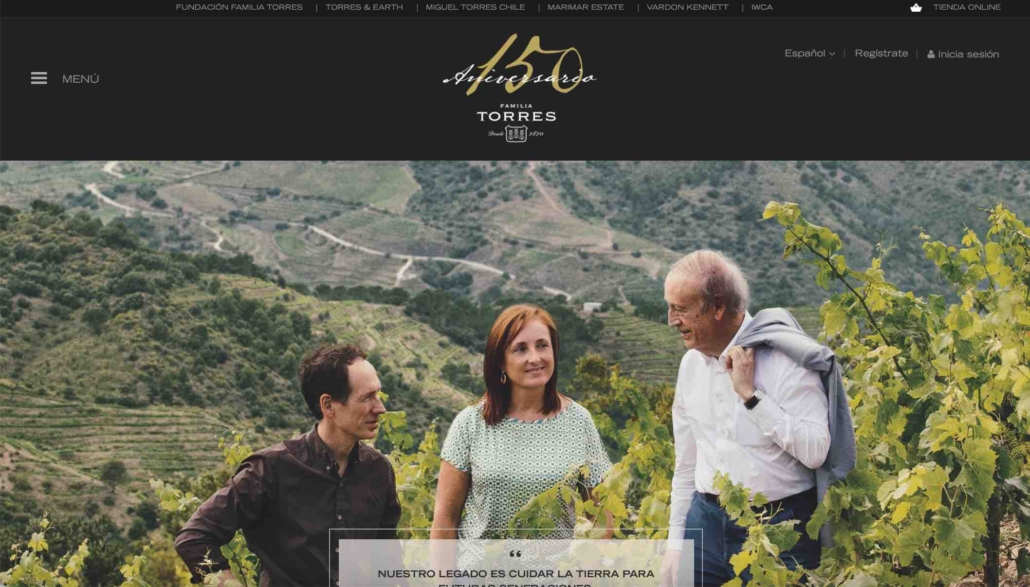

First development of a PWA for Bodegas Torres

The year that has just ended saw our debut in the field oBodegas Torres The year that has just ended saw our debut in the field of PWA–Progressive Web App development. Bodegas Torres decided to entrust us with the migration of its e-commerce platform to Magento 2 within their omnichannel strategy for the entire group. After analysing the characteristics of the project, we proposed development of a new Front End in ReactJS, and creation of an integrated PWA with a Magento 2 Back End, which will speed up browsing and improve online channel conversion.”> decided to entrust us with the migration of its eCommerce platform to Magento 2 within their omnichannel strategy for the entire group. After analysing the characteristics of the project, we proposed development of a new Front End in ReactJS, and creation of an integrated PWA with a Magento 2 Back End, which will speed up browsing and improve online channel conversion.

The project is still in execution and we estimate that it will be ready for delivery in April 2021.

We create an integrated PWA with a Magento 2 Back End for Bodegas Torres

Implementation of a BOM system for CoverCar

An entirely different undertaking was the project for CoverCar, a company dedicated to stamping, cutting and sewing of textile covers and interiors for cars. As part of the project to implement the MRP system developed at the time by ASMWS and integrated with the SAP B1 ERP system, we designed and implemented a new tool to manage the BOM–Bill Of Materials system for them. We did this alongside customer order processing via EDI. The main objective of the BOM system is to feed the MRP—Material Requirements Planning system when determining how many components are needed, as well as when the Master Production Plan is to be executed. This is translated into a series of purchase orders and the manufacture of the materials necessary to satisfy the demand for the end products.

Concerning BOM system management and maintenance, we have managed to streamline and automate the Commercial and Engineering processes transversally and integrated them with the Purchasing, Logistics and Quality areas.

Covid-19 has forced us to rethink a lot of things, but at least one or two have remained the same for us: perseverance and teamwork, which are two good ways to overcome adversity.

Click here if you want to read the first part of the Summary of the year